Say goodbye to manual inspections

Three reasons why Condition Based Scheduled Maintenance is a game-changer for predictive maintenance

Three reasons why Condition Based Scheduled Maintenance is a game-changer for predictive maintenance

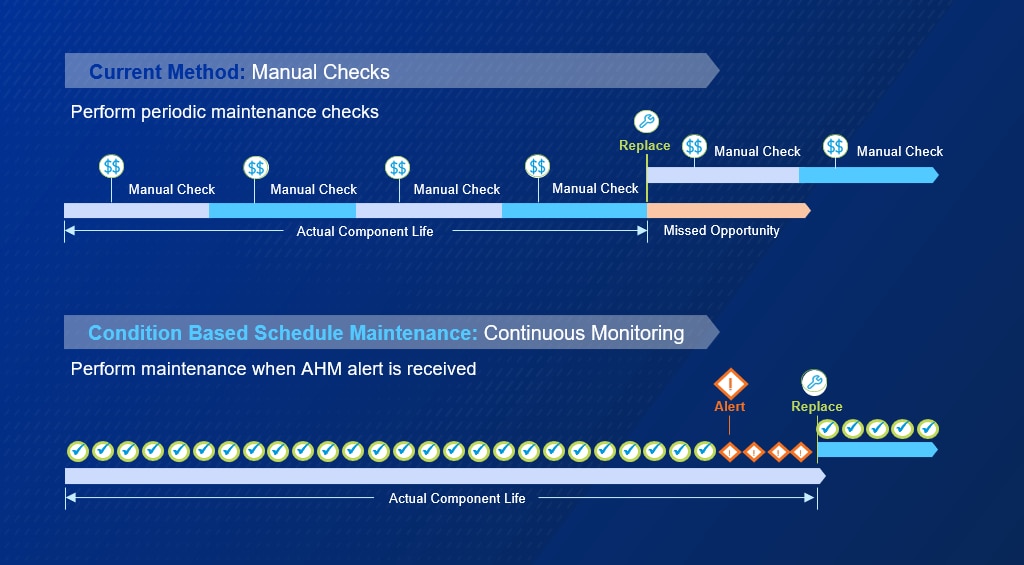

For decades, the aviation industry has relied on fixed intervals for inspections and maintenance. Manual maintenance checks, performed at regular intervals to maintain airworthiness compliance, come with costs—from labor expenses to premature component replacements and disruptions to operations. Mechanics would inspect aircraft at predetermined times, even if no issues were present, resulting in inefficiencies and higher costs.

With the introduction of Condition Based Scheduled Maintenance (CBSM), this paradigm has shifted. Airlines can now leverage real-time data from aircraft sensors to determine exactly when maintenance is needed. This regulator-approved solution represents a groundbreaking evolution, enabling operators to replace manual inspections with data-driven decisions and reducing maintenance burden.

The transition to CBSM has been driven by collaborative efforts between the Maintenance Programs Industry Group and the regulatory-led International Maintenance Review Board (MRB) Policy Board, resulting in the approval of a new logical process for scheduled maintenance development. This approach allows sensing systems to replace or alter existing on-aircraft scheduled maintenance requirements outlined in the Maintenance Review Board Report (MRBR).

At the core of CBSM is Integrated Aircraft Health Management (IAHM), a process that continuously monitors an aircraft’s health through onboard sensors. These sensors capture critical data, which is then analyzed remotely to:

This proactive approach reduces reliance on physical inspections and enables airlines to efficiently perform mandatory airworthiness tasks using sensor data.

The following initial tasks are intended to demonstrate the system’s capabilities and enable initial implementation, laying the groundwork for broader adoption, additional content and future enhancements.

Condition Based Schedule Maintenance represents a pivotal step forward for airlines, enabling them to transition from a fixed schedule to a condition based maintenance strategy. By harnessing the power of real-time sensor data, CBSM helps operators achieve unparalleled levels of efficiency and cost-effectiveness.

The first CBSM tasks, focused on tire pressure, brake wear, and fuel filters, have already been approved for the Boeing 787. These advancements mark a significant milestone in aviation maintenance, with more tasks under evaluation to further transform traditional maintenance practices.

Ready to optimize your aircraft's time in the sky? Contact us today and experience the benefits of CBSM firsthand.